Project Overview

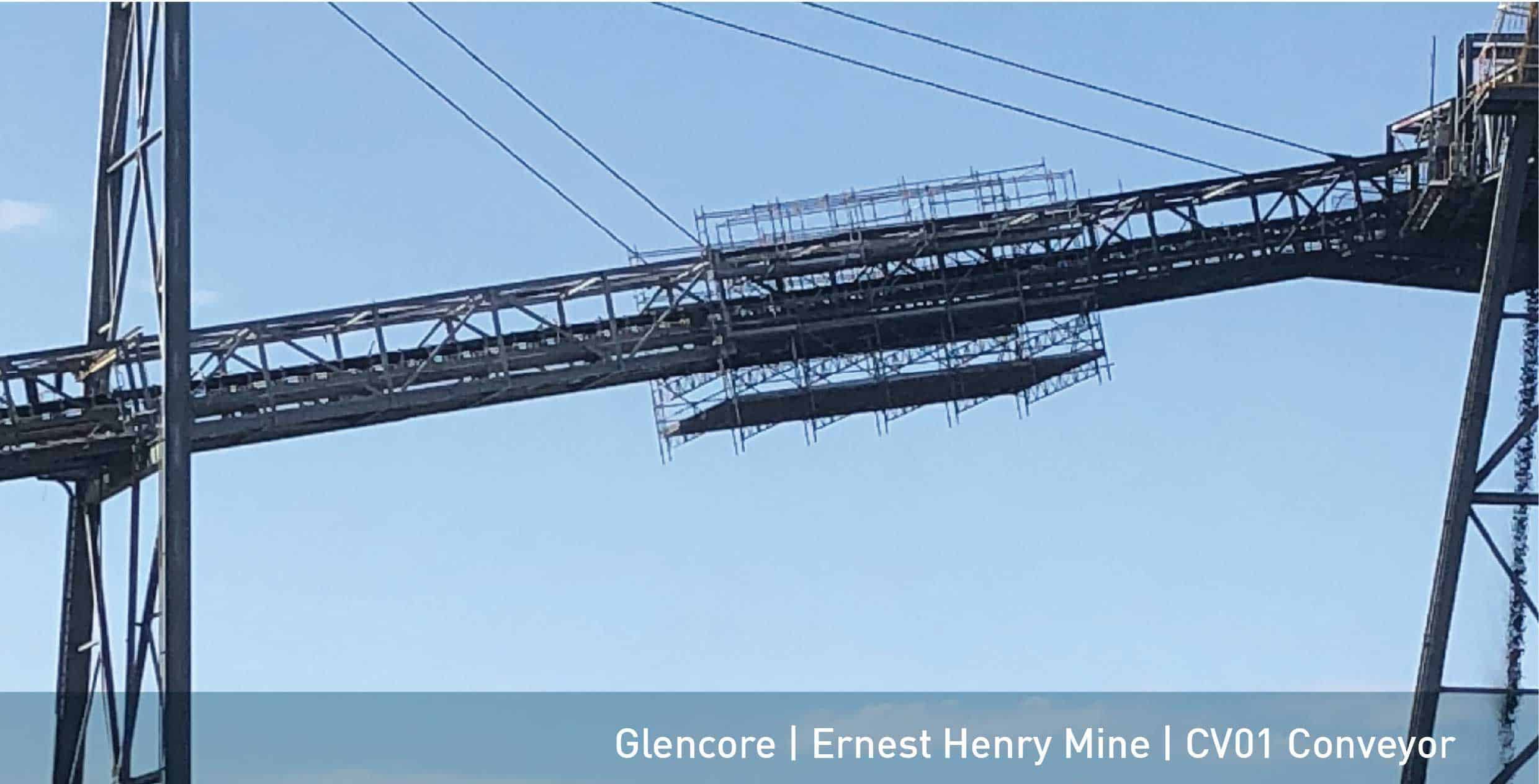

Glencore – Ernest Henry Mine – CV01 Conveyor

In mining and resource facilities, delays and downtime costs are generally much more expensive that the overall project costs. That is why it is critical to design and engineer scaffolding solutions based around 3 key things. Time, Cost and Safety.

The CV01 Conveyor is fed from the underground mine and transfers the ore to the stockpile before going through the crusher and into the mill. The steelwork required significant structural repairs and access to blast and paint.

The entire project was reverse engineered based on the structural assessment of the conveyor structure. Once we knew the capacity of the conveyor, we worked backwards in reverse to design the scaffolding using the least amount of equipment to keep the weight to a minimum but also installing the maximum length as possible. The project was broken into 4 sections and the scaffolding relocated from one area to another on completion.

Due to the increased risk of working at such height and materials handling, the Benchmark team used 3D modelling and animation to demonstrate the safe work methodologies and allow all parties to be trained and understand the tasks before arriving on site.